- Why use online color measurement equipment?

Today, color inspection equipment has essentially replaced manual labor and is widely used in production, primarily for final product inspection. However, this only prevents waste and defective products from reaching customers, while problems such as the waste of raw materials such as colorants and PVC during the production process, as well as labor costs, remain unresolved. If inspection equipment could promptly and quickly detect color differences in tape during the production process, issue real-time alarms, and automatically adjust the color ratio to achieve dynamic color balance, it would not only avoid the continuous generation of large quantities of defective products and reduce waste, but also significantly improve production efficiency and enhance the quality of plastic tape products.

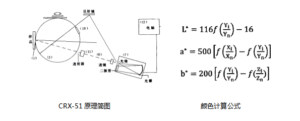

This would transform color inspection equipment from a “after-the-fact” testing device into a “real-time feedback” control device. The ST70 colorimeter launched by Guangdong Threenh Technology Co., Ltd. fulfills this role. The colorimeter ‘sonline color sensor utilizes the diffuse illumination Di:8° (diffuse illumination: 8° reception, mirror inclusion) geometry outlined in CIE 15-2004, the technical document on color measurement issued by the International Commission on Illumination (CIE). It also utilizes real-time dual-path grating spectroscopic spectral measurement, achieving near-zero matching error with the CIE 1931 tristimulus functions and achieving laboratory-grade measurement accuracy. A simplified schematic diagram of the principle is shown below:

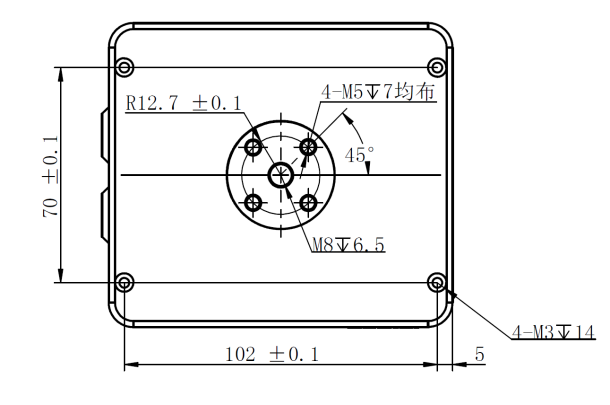

Steps for using a colorimeter’s online color sensor on a plastic tape production line: Step 1: Install the device at the measurement location, connect the power cord to power on the instrument, and connect the communication cable to the computer. See the figure below for the mounting hole diagram.

Colorimeter dimensions and installation hole diagram

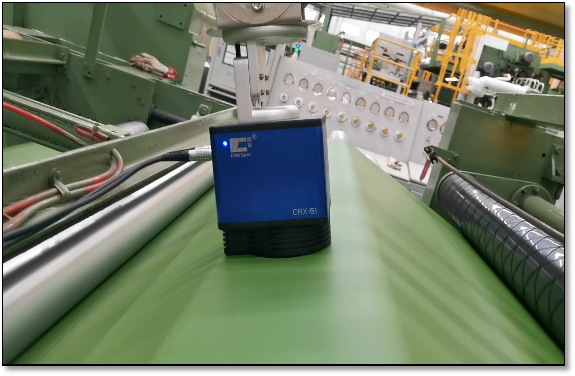

Schematic diagram of the colorimeter after installation

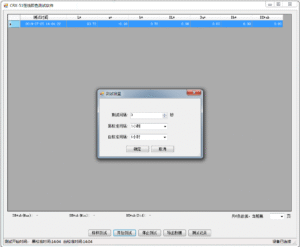

Step 2: In the colorimeter’s online color test software, click “Test Standard” (the instrument will automatically perform black and white calibration before testing the standard), then click “Test Sample”. A test setting dialog box will pop up. Set the test interval and blackboard calibration interval, then click OK. The instrument will then start automatic measurement, as shown in the figure below.

Colorimeter software test setup diagram

Step 3: The software measurement interface is shown in the figure below. The test data is stored in the software root directory in the form of a database. Click “Export Data” to export the tested data, which includes color information and reflectivity information.